SK Innovation ESG Report

Global Top Tier SHE Management

Safety, health, and environment (SHE) are integral elements of sustainable management. SK Innovation subsidiaries makes strenuous efforts to enhance employees’ physical and mental health by rolling out a range of health care programs. The safety of employees and suppliers is one of our core values pursued across the company and we strive to put in place SHE management systems that meet global standards and minimize safety accidents to zero. We also endeavor to lead resource circulation through aggressive waste recycling at our business sites.

SK Energy operates a safety management committee and a consultative body within the company to prevent the leakage and accidents of chemicals, establishing a global top-tier safety, health, and environmental (SHE) management system. In addition, by mandatorily reflecting safety management, including chemical leakage, in the evaluation of the management and members of the company, it operates an ESG management policy that clarifies supervision and responsibility for the SHE management.

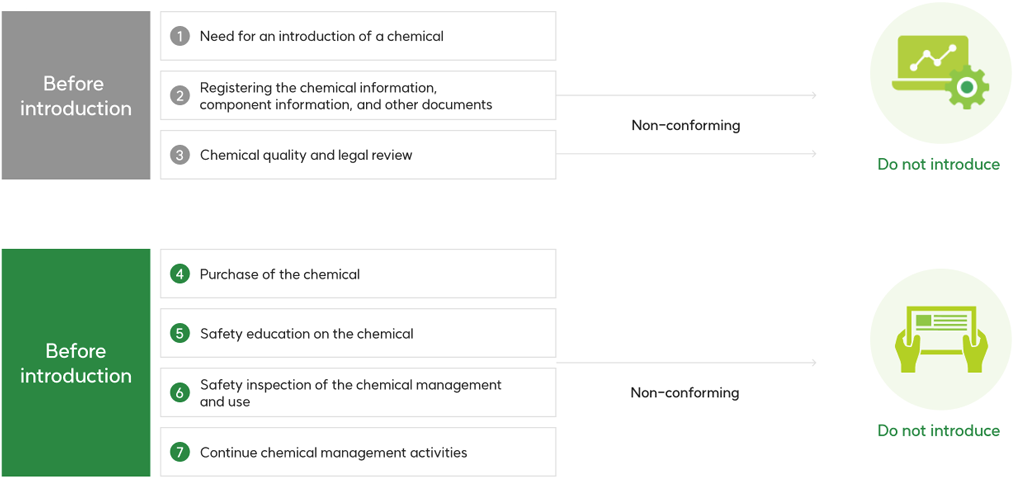

To manage high-risk chemicals, we thoroughly monitor domestic and international environmental regulations and introduce the integrated chemical management system Hi-Chems to minimize chemical-related risks.

An integrated chemical management system

An internally developed system for identifying stakeholder requirements for various chemical regulations and reviewing and managing the hazards of chemicals across departments

SK Energy has developed and applied an Operation Training Simulator that offers indirect experience of 286 emergency response scenarios across 11 processes. We also conduct facility integrity assurance activities, including corrosion inspection of vulnerable offshore facilities and explosion-proof facilities for instrumentation/electrical equipment. Moreover, we have established and been executing a facility safety investment plan of over KRW 10 billion by 2024 for the management of chemical leaks.

| Category | 2020 | 2021 | 2022(e) | Notes |

|---|---|---|---|---|

| Ulsan CLX Chemical Leakage Prevention Facility Investment | 2.6 Billion won | 4.1 Billion won | 5.7 Billion won |

We have adopted advanced inspection methods such as LDAR and RBI (Risk-Based Inspection) to measure and manage over 900,000 leak sites at our business sites at least once a year. We are committed to comprehensive safety management throughout the entire process of chemicals by providing stakeholders with Material Safety Data Sheets (MSDS) as a mandatory procedure during the transportation and sales process.

Chemical-related environmental audit performance and plans (2021)

| Category | Target | Result | Notes |

|---|---|---|---|

| ISO 14001 audit | SKE |

(Chances for improvement) Twice (Minor non-conformity) None (Major non-conformity) None |

Corrective actions completed |